Key takeaways

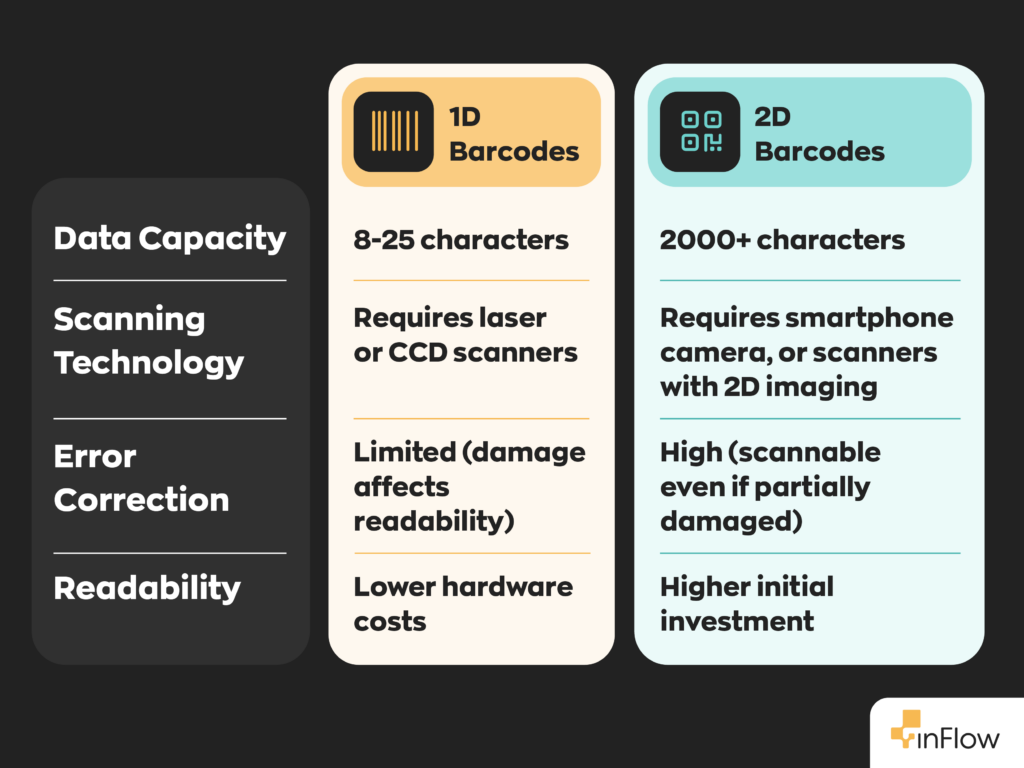

- The difference between 1D vs 2D barcodes lies in how each stores data. 1D barcodes store data linearly and are read from left to right, while 2D barcodes store data on both the x and y-axis.

- 2D barcodes feature built-in error correction, making them more reliable even if partially damaged. They can also store more data while often being smaller than 1D barcodes.

- 1D barcodes are more affordable and widely supported, whereas 2D barcodes require barcode scanners with a 2D imager and software that supports 2D barcodes.

- Both types of barcodes have plenty of real-world use cases. 1D barcodes remain dominant in retail, inventory management, shipping, and manufacturing, while 2D barcodes are increasingly used in healthcare, ecommerce, marketing, and interactive product packaging.

- Businesses moving to 2D barcodes may need to upgrade their hardware, change their workflow, and train their employees, especially if they rely on older laser-based scanners.

- inFlow supports both 1D and 2D barcodes, offering barcode generation, custom label printing, and scanning to help businesses improve accuracy and streamline inventory management.

Of all the business tools in use around the world, none are quite as widespread as barcodes. They’ve been a cornerstone of business operations since their introduction in the 70s, and that doesn’t appear to be changing anytime soon. That’s not to say that barcodes won’t continue to evolve. With technological advancements, we’re starting to see a shift from the 1D barcodes that have dominated the landscape to 2D barcodes.

As the barcoding landscape changes, many businesses are curious about the differences between 1D vs 2D barcodes. So, today, we’ll be going over those differences and why you might want to consider using one over the other.

1D vs 2D barcodes: what’s the difference?

In super simple terms, 1D vs 2D barcodes can be broken down into how each stores data. Barcodes may look like meaningless black-and-white patterns to the human eye, but machines can read them instantly.

You can think of a 1D barcode as reading a book. There’s really only one correct way to read it: left to right. Similarly, barcode scanners read 1D barcodes in a single, linear order. For this reason, we sometimes call them linear barcodes. These are the barcodes traditionally found on product packaging, shipping labels, and inventory tags.

2D barcodes work a bit differently. Rather than a single, linear orientation, they store information on both the x and y-axis. While this makes them more complex, it also means they can hold much more data.

For example, the most common 1D barcode is the universal product code (UPC), which can hold up to twelve characters. By comparison, the QR code, a popular 2D barcode, can hold up to 7089 characters, depending on the character type.

Despite this difference in data density, 2D barcodes are often physically smaller than their 1D counterparts.

What other differences are there between 1D and 2D barcodes?

Of course, as the newer of the two barcode types, 2D barcodes have a few extra features. One of the most notable ones is error correction. 2D barcodes use Reed-Solomon error correction to fill in the gaps and recover lost data. This makes their error rate much lower despite carrying many times more characters.

Similarly, 2D barcodes tend to be more readable despite their size. This makes them better suited for applications requiring speed and accuracy.

2D barcodes can be more expensive

While 2D barcodes are overall more capable, one point in favor of 1D barcodes in the 1D vs 2D barcodes debate is their affordability.

This has more to do with the technology needed to read 2D barcodes than the format itself. Because 2D barcodes store data on two different planes, scanners read the information differently. This means not all barcode scanners can read both 1D and 2D barcodes, and the ones that can are usually more expensive.

In fairness to 2D barcodes, though, the price gap between the two formats has shrunk dramatically. And this hasn’t gone unnoticed. GS1, the official supplier of global barcodes, plans to move over entirely to 2D barcodes by 2027. That’s one of the great things about technology. As it improves, it tends to become more affordable as well.

Overall, 2D barcodes are more versatile than 1D barcodes, so it’s no real surprise that 1D barcodes are slowly being phased out. For now, though, they have their place.

Real-world use cases: 1D Barcodes

What makes 1D barcodes so great is their accessibility. While you’ll still need to purchase official GS1 barcodes to sell your products in any major retailer, you can create your own barcodes for other purposes. Here are some of the most common use cases for 1D barcodes:

- Retail & Point of Sale (POS)— UPC and EAN barcodes are the standard for product labeling in retail stores across the globe. These 1D barcodes enable fast and accurate checkout and help businesses track their inventory levels in real time as they make sales.

- Warehousing & Inventory Management—Barcode symbologies such as code 39 and code 128 are great 1D barcode options for internal inventory management. You can create these barcodes using a free online barcode generator or font, making them attractive to small businesses on a tight budget. These barcodes are great for receiving, picking, packing, and shipping.

- Shipping & Logistics—1D barcodes are essential for tracking shipments and managing supply chain logistics. Businesses can scan barcodes to monitor parcel movement and delivery status in real time.

- Manufacturing & Assembly—Production facilities handle a lot of inventory due to all their raw materials, intermediate goods, and finished products. 1D barcodes are an inexpensive way to track these items as they travel through the manufacturing process.

Real-world use cases: 2D Barcodes

The added character count of 2D barcodes brings many more possibilities. Some of these use cases are:

- Product Packaging—QR codes have started to be implemented on product packaging to link customers to instructional videos, nutritional facts, reviews, promotional offers, and more.

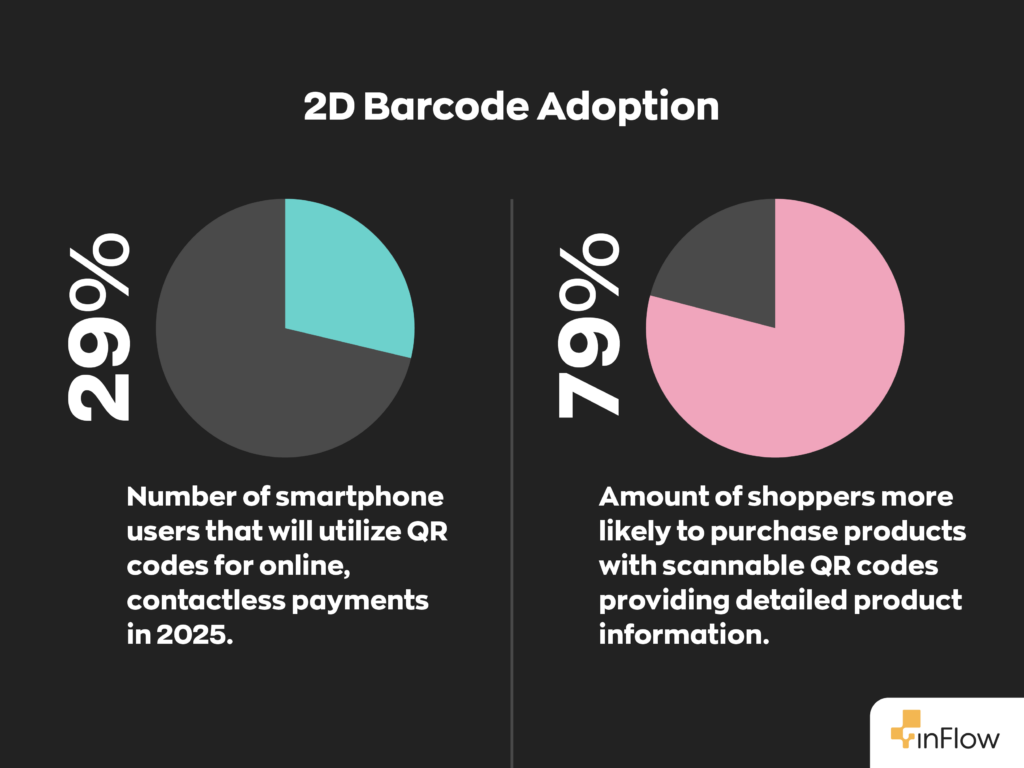

- Ecommerce—Just because you don’t have a physical store doesn’t mean you can’t reap the benefits of barcodes. Ecommerce shops can use 2D barcodes for digital receipts and even mobile payments.

- Healthcare—Hospitals and labs are environments where having more information readily available is invaluable. That’s why we see 2D barcodes on patient wristbands and charts that store medical histories and medications. Medication packing also uses 2D barcodes to track expiration dates, lot numbers, and dosages.

- Advertising & Marketing—QR codes are popping up everywhere these days, from posters and advertisements to restaurant menus. We can use them to claim promotional codes, access social media pages, or place an order at a restaurant. Since 2D barcodes are capable of storing URLs, the possibilities are endless.

Transitioning from 1D barcodes to 2D barcodes

If you’re already using 1D barcodes and considering switching to 2D barcodes, there are some common roadblocks you should keep watch for.

Hardware upgrades

We mentioned above that scanners need a 2D imager to read 2D barcodes. Many older laser scanners don’t have this feature, so you may have to replace all your barcode scanners.

The good news is that smartphones can scan QR codes with their cameras, so if you’re strapped for cash, you can get by using your cellphone. This is a great option for inFlow users since we have a mobile app, which means you can scan your items right inside of inFlow from one device.

Barcode printers are another piece of hardware you should consider upgrading to ensure the best print quality. While 2D barcodes make use of error correction, they’re not foolproof. A greater data density also means more opportunities for corruption or damage. A smudge or two might not make a difference, but error correction can only compensate for so much. Ensuring print quality might require more upfront costs but could save time- and money- in the long run.

Workflow adjustments & employee training

Not all systems and workflows support 2D barcodes. This could require a major overhaul of your systems, software, and workflows. Additionally, if you introduce new hardware or equipment, more training will be necessary to bring everyone up to speed.

Depending on your industry, you may also need to consider potential regulations. It’s your duty to know what those regulations are and ensure compliance. This may include the need for additional employee training, such as in the healthcare industry, where sensitive patient information is commonly involved.

How inFlow can help with both 1D and 2D barcodes

No matter which type of barcode you choose, having the right software is crucial. Our software inFlow is built to support both 1D and 2D barcodes. With inFlow, you can:

- Generate barcodes for products, locations, or asset tracking.

- Design and print custom barcode labels with our built-in label designer.

- Scan barcodes with your mobile device, the inFlow Smart Scanner, or any other barcode scanner.

By leveraging inFlow’s barcode inventory system, businesses can improve their accuracy and optimize inventory tracking and order fulfillment. Whether you use UPC, Code 39, or QR codes, inFlow has you covered.

0 Comments