Key takeaways

- Automated inventory management systems use barcodes, real-time updates, reorder points, and integrations to reduce human error and increase speed.

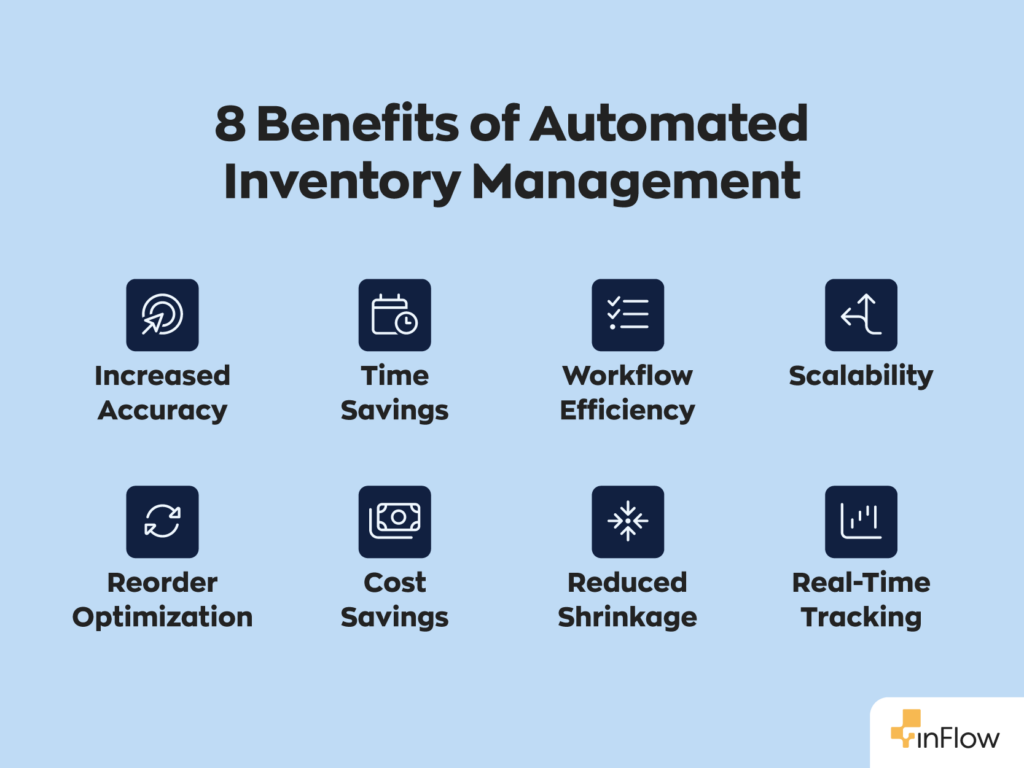

- The benefits of automated inventory tracking include improved workflow efficiency, fewer errors, and improved demand forecasting.

- Key features in automated inventory management software include barcodes, perpetual inventory tracking, integrations, reporting, and reorder point notifications.

- Implementation involves identifying business needs, setting up automation like barcodes and integrations, and calculating reorder points.

- Automation will save businesses money through reduced labor requirements, faster workflows, and minimized errors.

AI and automation seem to be all anyone talks about these days, and as it turns out, there’s a pretty good reason for that. It’s hard to ignore the value AI and automation bring. These key features can help businesses through process automation, predictive analysis, and automated inventory management.

So, today, we’ll focus on automated inventory tracking, including its benefits and what to look for when implementing an automated inventory management system.

What is an automated inventory management system?

Inventory management, in theory, is pretty simple: track products and assets as they move through your business. In practice, though, it’s much more complex. You’ll need to juggle many moving pieces, like sales orders, purchase orders, stock levels, price, inventory movement across multiple locations and sublocations, and so on.

Manually tracking these things is possible but usually inadvisable. Human error is a constant, and we are especially susceptible to mistakes when performing repetitive, menial tasks. Automated inventory management seeks to remedy this by using software to minimize the need for human input. Automated inventory management software achieves this through various means ranging from barcodes to automated reorder notifications.

Unlike humans, computers are great at handling repetitive tasks. They can also integrate with other systems, making them ideal tools for many different applications.

What are the benefits of automated inventory tracking?

Automated inventory management has two main benefits: speeding up workflow and reducing human error. This is where barcodes shine. Scanning a barcode is much easier and faster than manual data entry, not to mention much more accurate. While barcodes may not be the most exciting automation available, they arguably bring the most value.

Scanning barcodes may only save you a few minutes here and there, but that time will add up quickly. Not to mention, barcodes work in a very binary way; they either scan or they don’t. Unlike manual data entry, where it’s easy for someone to make a mistake.

Automated inventory tracking is also a great way to protect your business from the unexpected. Inventory management software like inFlow has built-in reorder points, which means when your stock levels dip below a specific level, the system will send an automated notification to let you know it’s time to order more. If you’d like to see machine‑learning forecasting in action, you can book a demo with StockTrim—a forecasting add‑on for inFlow that analyzes sales data and suggests when to reorder.

Another incredible benefit is the data that inventory tracking yields. Automated inventory management software tracks sales as they happen, providing a comprehensive log of when they occur. Collecting this data will improve a business’s demand forecasting in the long term. These forecasts help guide business decisions and can also help identify cost-saving measures.

Key features for automated inventory software

Not every automated inventory management software functions the same, but unsurprisingly, they tend to operate on the same principles. In the same vein, there are some must-have features that any automated inventory management system should have (some of them we’ve already touched on).

Barcodes

We’ve mentioned barcodes a couple of times already, and that’s because much of automated inventory tracking hinges on them. When an employee scans a barcode, the machine matches it to the relevant product within the barcoding software. This simple function allows you to automate several tasks, such as picking, stock adjustments, cycle counts, and more. Without barcodes, the efficacy of automated inventory management decreases drastically.

Real-time tracking

Real-time tracking means that inventory information updates whenever a change occurs. Accurate assessment is crucial when making business decisions; real-time tracking always provides an accurate picture. This is particularly useful when your business operates from multiple locations. When you take something from one location, all other locations will be automatically updated.

Integrations

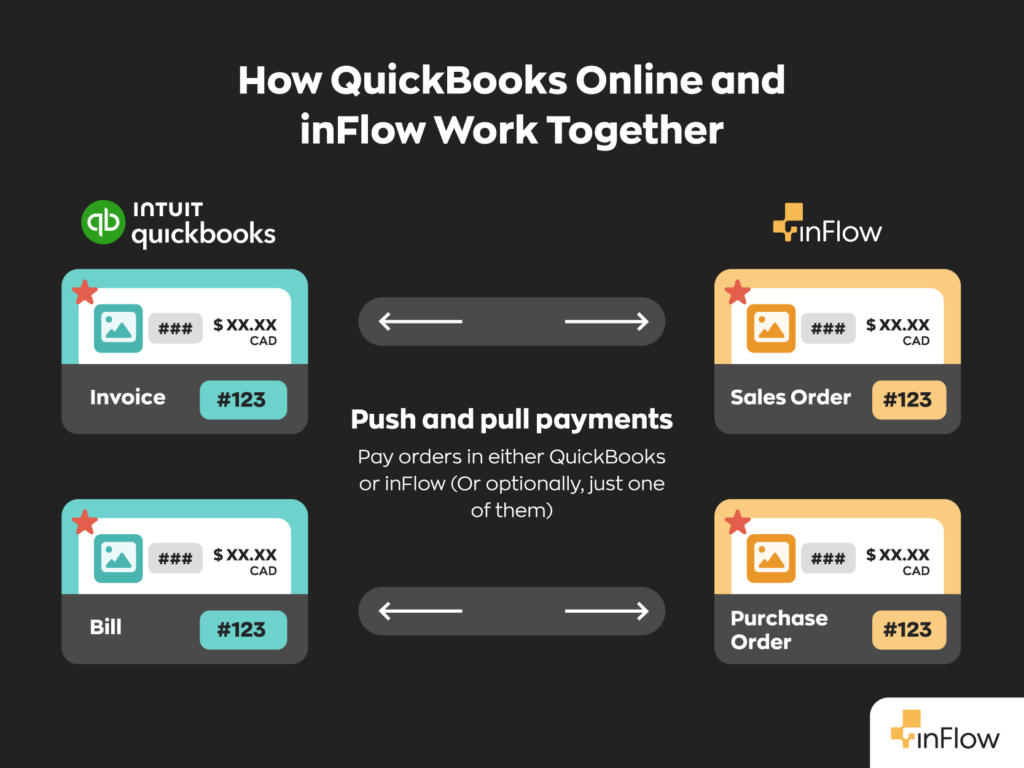

These days, businesses often rely on multiple different software solutions to perform various tasks. For example, you might use inFlow for automated inventory management and QuickBooks Online to handle accounting and other financial information. It’s important that these systems can talk to one another, which requires a robust list of integrations.

For instance, inFlow integrates with QuickBooks Online, which automates two-way payment sync. This allows you to push payments from inFlow to QuickBooks Online and pull payments from QuickBooks Online to inFlow—no more double data entry.

Reporting

Inventory management software stores quite a bit of data. It collects sales information like quantity, date of sale, price, and so on. This data is super helpful, but organizing and analyzing it in a meaningful way can be tricky. Thankfully, automated inventory management software will handle the grunt work for you. As a result, all you need to do is click a button to generate various reports easily.

Reorder point notifications

Inventory drives revenue—without inventory, there can be no purchases. That means you’ll need to stay on top of your inventory levels to avoid potential stockouts. Reorder points are a great way of automating this process. They ensure you maintain the perfect balance of stock to prevent both stockouts and carrying excess inventory.

How to implement an automated inventory system

If you’re looking to implement your own automated inventory management, it’s important to remember that your needs are unique. Even businesses operating in the same sector or niche may have different procedures. For that reason, we can’t offer a perfect guide to finding a solution, but we can provide some general steps.

First, identify your business needs. Are you looking to improve the accuracy of your stock level records? Are you trying to reduce inventory shrinkage, or is there something else entirely? Your business needs will ultimately decide the ideal solution, so it’s important to know what exactly you need while looking.

Once you find an automated inventory management solution with all the features you want, you’ll need to set up your automation. This step is easily the most time-consuming but is a one-time process. Once you’re set-up, you should be good to go for a while.

If you plan to use barcodes, you must generate, print, and label all your inventory. To use reorder points, you’ll need to calculate them for each of your products. If you’re interested in integrating your various software solutions, you’ll need to go through the process of connecting your software solutions.

Does it save money for small businesses?

Short answer: yes.

While automated inventory management software often has a recurring cost in the form of a subscription, it still saves money in the long run. This is mainly because it dramatically reduces the need for staffing. Labor is expensive, and reducing workforce requirements while allocating it elsewhere is a tremendous boon.

This is without taking into account additional costs incurred by human error. Human error can be exorbitantly costly, and avoiding it as much as possible is yet another reason to favor automated inventory tracking.

0 Comments