Key takeaways

- Construction procurement is a strategic process focused on long-term goals like supplier/vendor relationship management and involves sourcing materials and specialized labor.

- Procurement in construction is crucial because projects rely on a steady supply of labor and materials. Effective construction procurement will help businesses manage fluctuating costs supplier shortages, and avoid delays.

- Smaller construction companies often face resource constraints, including limited cash flow and smaller procurement teams, which can hinder their ability to secure reliable suppliers.

- Key procurement steps include identifying needs, evaluating suppliers, requesting quotes, negotiating terms, and issuing purchase orders while maintaining clear documentation like requisitions and contracts.

- Some best practices for efficient procurement in construction include building strong supplier relationships, leveraging accurate demand forecasts, and using specialized inventory and procurement software.

- The procurement process involves suppliers (raw materials), vendors (finished products/services), contractors (skilled labor), and project stakeholders (clients), all of whom play distinct roles in project success.

Construction procurement is a strategic process for managing a construction project. It involves numerous methods to ensure that services, materials, and labor are delivered and allocated efficiently. Effective procurement ensures transparency, risk management, and quality assurance by providing clear project requirements, selecting qualified contractors, and overseeing the project’s completion.

Why is construction procurement important?

Construction businesses rely on maintaining a steady supply of both labor and materials to deliver projects on time. Procurement is an integral part of maintaining a consistent workflow. This is due to a few factors.

Construction projects are naturally large-scale, expensive endeavors. For example, the average cost to build a house in 2024 was $428,000. Not only are they expensive, but they also take time to complete. Building a relatively small project, like a house, can take weeks, months, or even years. What does this mean for construction procurement?

First and foremost, construction material costs fluctuate regularly, and considering that construction projects require so many materials, even slight price differences can lead to hundreds or thousands of dollars. And because of the extended time frames, construction projects are often susceptible to multiple fluctuations in price.

Another common issue is supplier shortages. Construction requires a broad range of materials, many of which are in high demand and subject to seasonal market shifts. Sourcing these materials is detrimental to finishing on schedule. However, finding multiple reliable suppliers can be difficult and takes time.

Poor inventory management is another common mistake that can be disastrous. An inadequate tracking system means you have the potential to run out of a key component at a critical moment. In the worst-case scenario, this could throw off the timeframe for the entire project.

Lastly, logistical inefficiencies can have a cascading effect. Shipping delays and other complications are common. If every shipment is a day late, that adds up to a lot of lost working time.

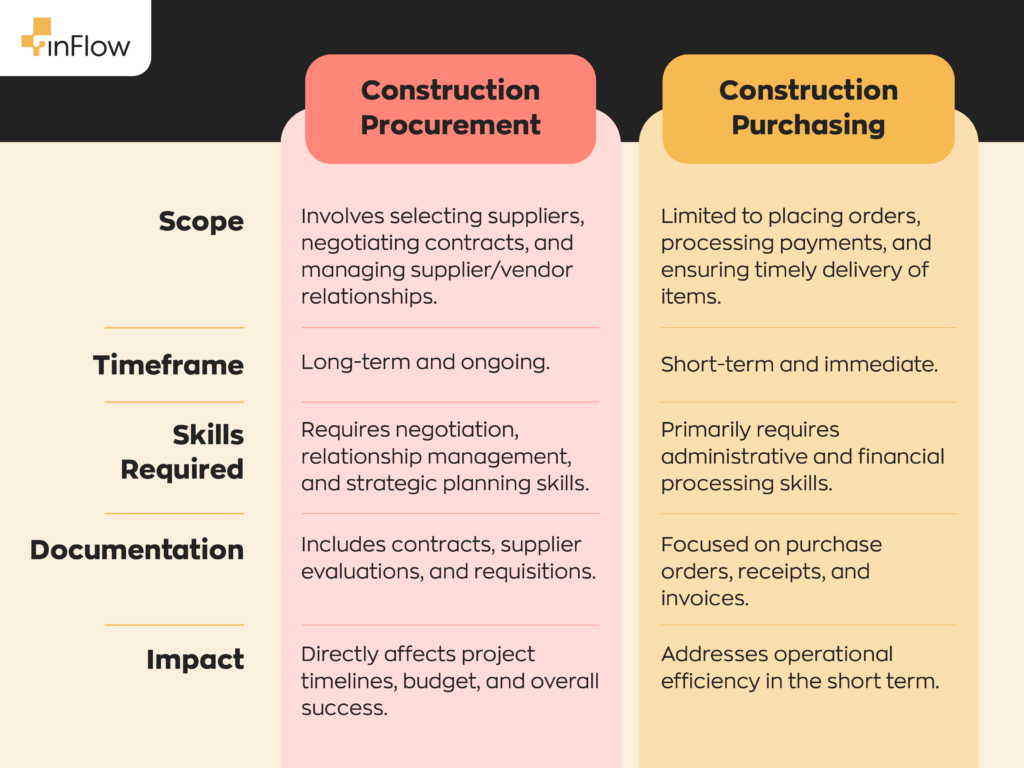

Procurement vs. purchasing in construction

It’s easy to mistake procurement and purchasing for being one and the same. After all, the two practically share definitions. However, the differences between construction procurement and purchasing are important.

One significant difference between purchasing and procurement is the goal. Usually, businesses purchase something to solve an immediate problem, such as a lack of inventory. It can also be a problem unrelated to sales, such as emergency repairs for the warehouse or offices.

Procurement is a more strategic process. It generally has more to do with long-term goals, such as selecting suppliers and managing relationships with those suppliers. Effectively managing these relationships will require someone with a specific skill set and experience in procurement.

However, procurement in construction extends beyond just materials and can also involve sourcing specialized labor.

Unique procurement challenges faced by small businesses

In 2023, the U.S. Small Business Administration reported 33.3 million small businesses in the U.S., making up 99.9% of all U.S. businesses. There are challenges to maintaining any business, but the construction industry poses unique ones for smaller businesses.

For one, they tend to operate with fewer resources at their disposal. This can include materials, tools, workforce, and storage space. And, of course, there are reduced cash flows to consider. When you operate with a smaller safety net, it can be easy to fall into the red zone and incur losses.

Smaller organizations also tend to have smaller teams dedicated to construction procurement. This might not seem like a big deal, but finding suppliers takes time. Having more staff dedicated to finding them is often worth the extra cost, but not every company can afford it.

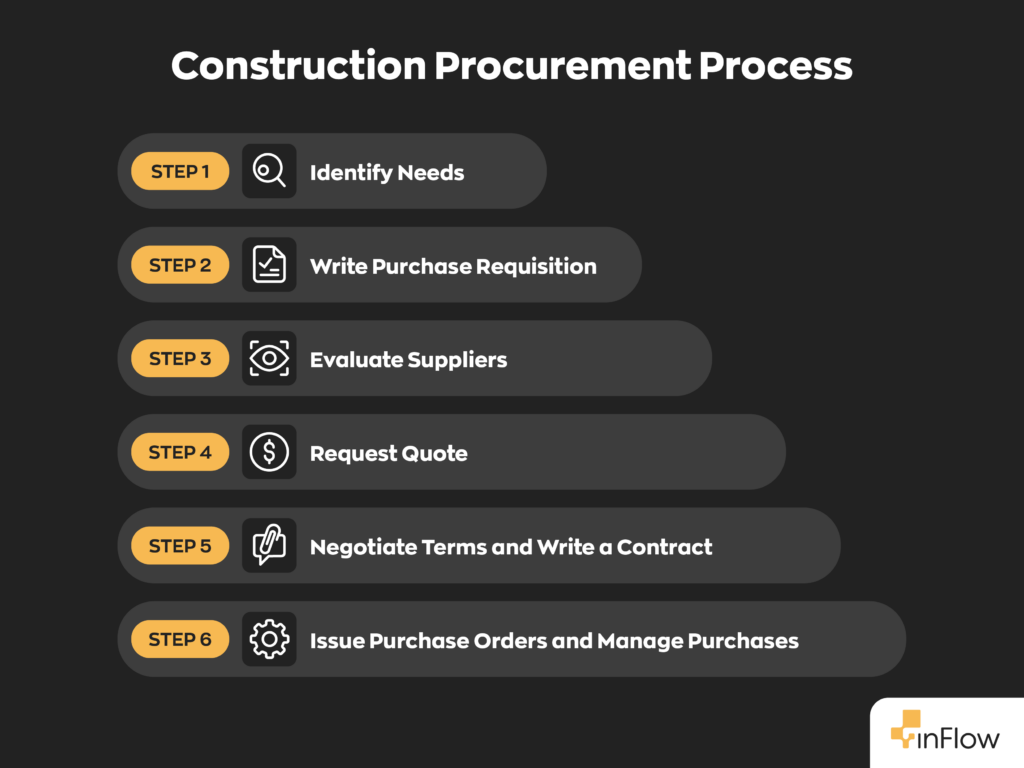

What does the construction procurement process look like?

In general, the construction procurement process looks fairly similar between projects. In most instances, you can expect the process to look something like this:

- Identify needs: Before purchasing anything, it’s essential to determine what the project requires. In construction procurement, this often means figuring out the necessary material quantities, but it also refers to sourcing different types of contractors. There’s a lot that goes into constructing a building, after all.

- Write a purchase requisition: Once the numbers are final, it’s time to write a purchase requisition. Some small businesses may be tempted to skip this step, but keeping a paper trail is important. It often becomes necessary somewhere else in the process.

- Evaluate suppliers: Many suppliers offer similar goods, but they may differ in price, as well as other aspects like quality. There are also reliability and lead times to consider. Even if one supplier looks like the perfect partner, it’s best to shortlist a few.

- Request quotes: Next, it’s time to make contact. Get in touch and ask for a quote regarding the on-hand project. As we said above, it’s best to contact more than one. Some vendors may be unavailable or limited in how much they can offer.

- Negotiate terms and write a contract: Afterwards, you’ll need to negotiate a price. Even if the vendor states one price, they may be able to offer better deals for bulk purchases. A contract is also important to protect both parties and maintain documentation.

- Issue purchase orders and manage purchases: Once all relevant parties agree, it’s time to purchase! Once materials arrive, that’s it — it’s your responsibility now. You’ll need to store them and maintain the supply on your own.

Depending on the project, procurement in construction may follow different steps. Some materials may require special permits or labor, and those introduce additional bullet points in the procurement process.

Construction procurement best practices

Keep in mind that a large part of construction procurement is managing relations. A supplier’s prices may increase to reflect the market, or they could find themselves in a shortage. These things happen, and it doesn’t mean you should cut ties and find a new supplier. Shortages and price increases often affect many suppliers, after all.

It’s also important to develop accurate demand forecasts. Procuring too many materials eats into profits, and procuring too few can halt progress. Accurate forecasting helps prevent these issues.

Managing inventory is another integral piece of the process. There are various types of inventory to consider, and losing track of materials can be catastrophic. Some construction materials may also require special storage. For example, some raw goods are more susceptible to humidity and require careful consideration.

Lastly, it’s imperative to leverage the right tools. In today’s digital age, that often means using software. Accounting software can keep your books up to date, and field management software, like inFlow, will help you track purchases and inventory levels. inFlow even integrates with accounting software like QuickBooks Online and Xero, eliminating a lot of double data entry.

Who are the key players in construction procurement?

We’ve referenced a few parties involved in the construction procurement process, but having a clear idea of roles is never a bad thing. For instance, “supplier” and “vendor” are often used interchangeably, but there’s some important nuance between the two.

- Supplier: Generally speaking, a supplier handles raw materials, such as concrete, lumber, and so on. They usually deal in huge quantities and leave the construction companies to handle the rest.

- Vendor: On the other hand, vendors usually sell a finished product or offer a specific service. For example, they may sell wooden furnishings like cabinets or offer advanced electrical work.

- Contractors: These individuals will make up most of the workforce. They’re usually skilled laborers like carpenters, roofers, or electricians. Making a structure habitable requires many niche skills; you’ll often need to find external parties that hold these skills.

Though they’re not directly involved, project stakeholders are also an essential part of the ecosystem. Since they’re the ones seeking a business to do work, they naturally have an interest in the rest of the procurement process.

Wrapping up

And there you have it! A lot goes into construction procurement, and it’s important to remember that project needs will differ. Some may require special permits, hard-to-source materials, specialized labor, and so on. Identifying those needs and adapting to them on the go plays a huge role in success.

0 Comments