Key takeaways

- Inventory accuracy reflects how well a business manages its stock and helps prevent issues like stockouts and overstocking.

- The inventory accuracy formula is: Inventory accuracy= (counted units / on record) * 100

- Barcodes and warehouse management software are two examples of technology that can help improve inventory accuracy.

- While technology is great, it’s not a replacement for physical inventory counts.

- Instead of full inventory counts, cycle counting in smaller batches improves accuracy without disrupting operations.

- Establishing standardized processes helps employees follow best practices and reduces mistakes.

- Well-trained staff are more accurate, leading to fewer errors and better overall inventory management.

- Monitoring and refining processes while leveraging tools will drive long-term business success.

For any business that carries physical goods, inventory accuracy is crucial. It ensures that you have the right products on hand and helps avoid problems like stockouts (or overstocking) while ensuring smooth operations. Inventory accuracy also goes a long way in keeping business owners informed about their company’s financials.

Inventory accuracy is arguably even more important for small to medium-sized businesses (SMBs) since they often operate on much smaller profit margins, which means there’s less room for error.

That’s why, today, we’ll be going over some strategies to help your business improve its inventory accuracy. Some are simple, while others are more complex, but each has merits. There’s a lot to go over today, so let’s get right into it!

What is inventory accuracy?

Inventory accuracy measures how closely a company’s recorded inventory levels match the actual physical inventory number. As mentioned above, inventory accuracy is crucial for avoiding various issues, such as stockouts or excess inventory. Problems like these can cripple your business, so it’s worth trying to stay ahead of them.

What is the inventory accuracy formula?

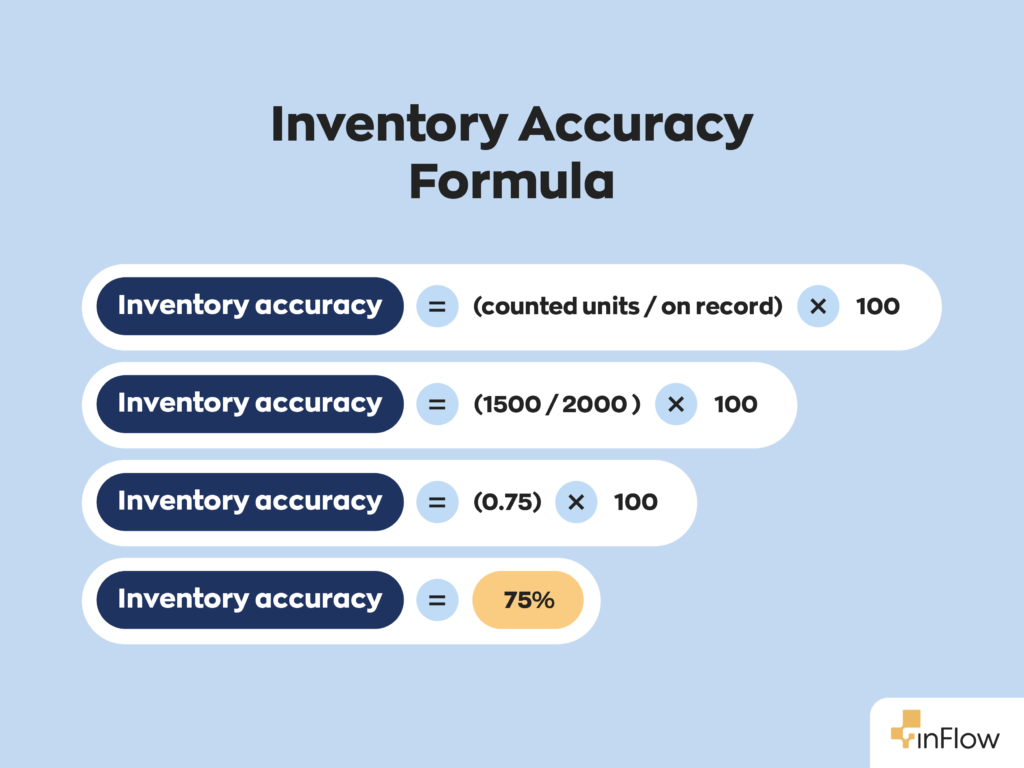

Luckily, calculating inventory accuracy is pretty simple. You just need to use the inventory accuracy formula, which looks like this:

Inventory accuracy= (counted units / on record) * 100

Simple, right? Let’s put it to work with an example. Imagine you own a tile business- you’ve got lots of little squares to keep track of. Let’s assume that your records say there are 2000 units available. However, after a cycle count, you realize you only have 1500 units on hand.

Putting those into the equation, we get the following:

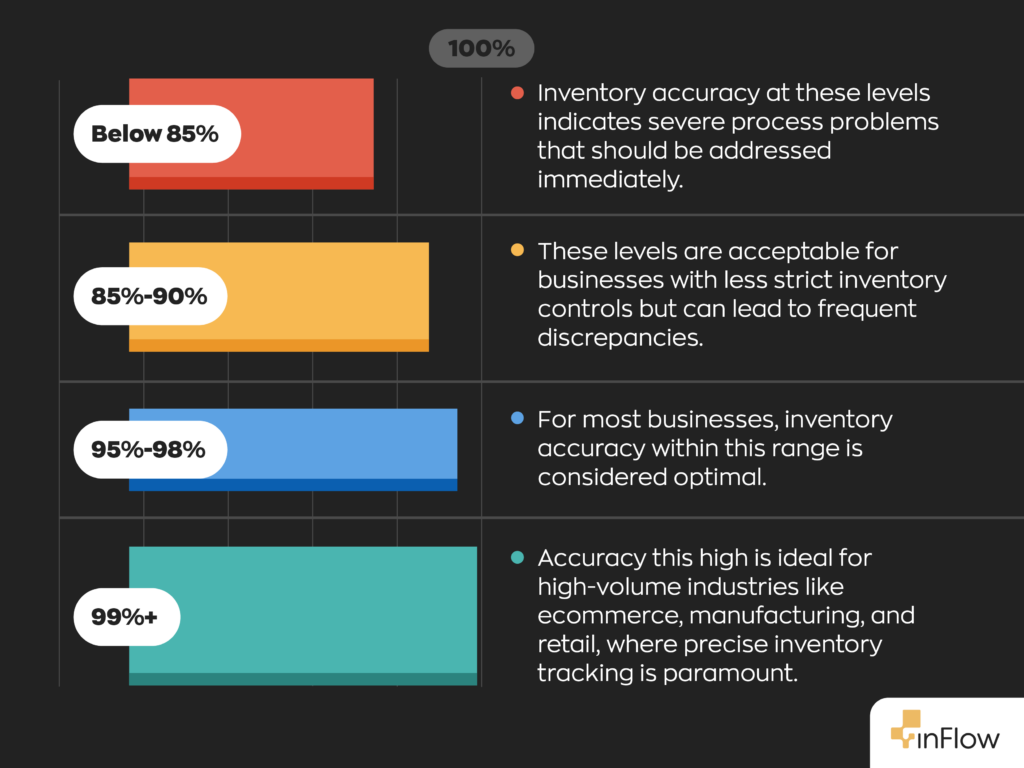

Remember—because we’re multiplying by 100, we express the answer as a percentage. Therefore, your inventory accuracy is 75%, which is considered subpar. It’s best to keep your inventory accuracy as high as possible, usually 95% or higher.

Common challenges in maintaining inventory accuracy

If you struggle to maintain high inventory accuracy, you’re not alone. Many SMBs face hurdles in keeping their inventory records accurate. Here are some of the most common challenges you’ll face:

- Human error—As much as we try to avoid it, human error is a constant. People are going to mess up. There’s no way to prevent it entirely, but you can minimize it.

- Theft—Most of the time, employees are good and trustworthy, but there’s always the occasional bad apple. Sometimes, those people will take advantage of your trust, so always remain vigilant.

- Inventory shrinkage—The most common and costly reason for poor inventory accuracy is inventory shrinkage. Its causes can range from poor inventory control to employee theft and outdated technology.

- Outdated technology— Technology is great. Obsolete technology, on the other hand, can cause all sorts of headaches. Make no mistake, using technology is a good thing, but make sure it’s not actively hindering you. You don’t need the latest and greatest, but you will need something that works as intended.

- Lack of regular audits—Don’t fall into the trap of thinking that using technology exempts you from doing inventory audits. You’ll still need to perform them regularly to maintain a high inventory accuracy.

- Seasonal fluctuations—The market answers to consumers, and consumers answer to the seasons—sort of. At the very least, very few people will buy winter jackets during the summer, and vice versa. These fluctuations can muddle the numbers, making it challenging to retain inventory accuracy.

5 ways to improve your inventory accuracy

If you know your inventory accuracy, you’ll have a much better understanding of where you’re falling short. No matter how well you manage your inventory, you’ll never avoid inventory shrinkage altogether. The trick is to minimize it as much as possible. Here are some tips to help you improve your inventory accuracy.

1. Use barcodes

Barcodes are the rock stars of inventory management, and for good reason. Employees can scan a barcode instead of painstakingly looking up product information. Barcodes save time, help track product flow, and reduce human errors. There is no denying that barcodes are the easiest way to increase your inventory accuracy dramatically.

Beyond improving inventory accuracy, barcodes are great for many different use cases, such as asset tracking. Some businesses get really creative and even use barcodes for shelving and documents. Fun fact: inFlow has a built-in inventory barcode system that allows you to create barcodes for any of your products with just a few clicks.

2. Implement warehouse management software

We humans are terrible at keeping track of a lot of little things at once. There’s no question about it. That’s why most modern businesses rely on warehouse management software. They use computers to track product flow in real-time, and while errors are not unheard of, they produce far fewer than manual data entry methods.

The best part? Many solutions, like our software inFlow, are cloud-based, meaning you can access them from nearly any device with an internet connection. They can even help make your dreaded cycle counts more manageable.

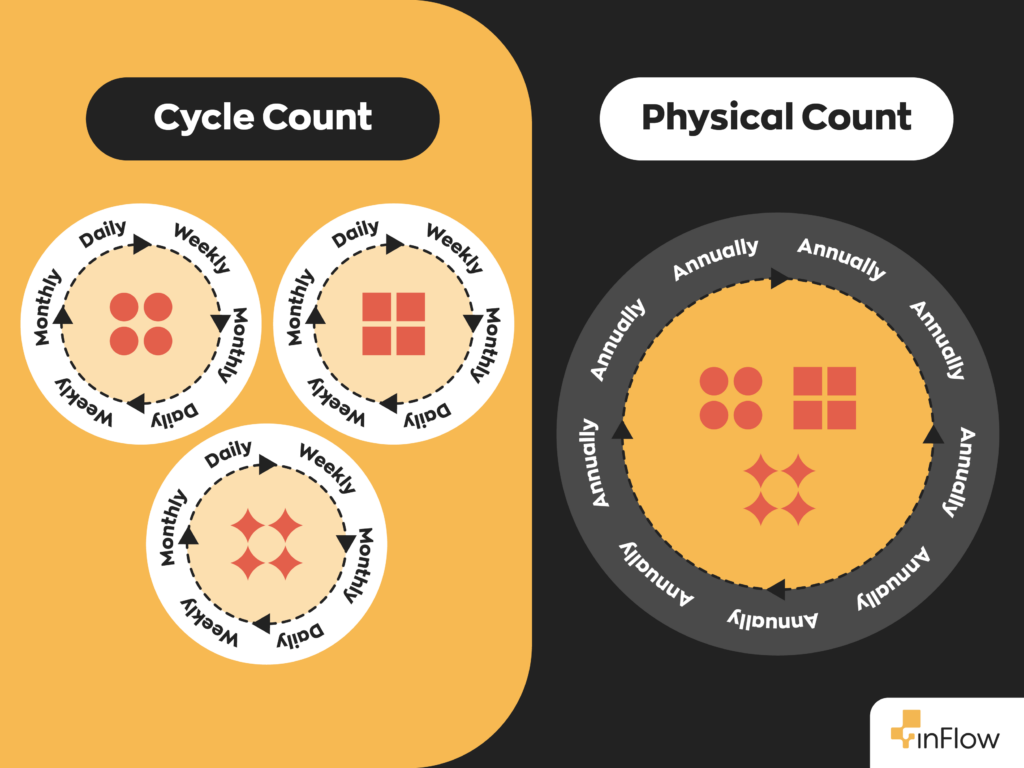

3. Perform regular cycle counts

It’s no secret that cycle counts are tedious and time-consuming, so some businesses avoid them altogether. However, we can’t stress enough how much of a mistake this would be. Cycle counts are necessary for anyone who wants to track and improve their inventory accuracy.

Instead of counting everything at once, cycle counts divide products into different subsets of inventory. Businesses then count the products in these categories one by one. This simple but effective method of compartmentalizing counts results in greater efficiency.

4. Establish standardization

Every business has different needs. For example, a chemical company will have a different process for handling its inventory than an auto shop. It’s essential to make your own rules and stick to them, as deviating could prove confusing.

Whatever your industry, establishing your own standardized processes pays off. It gives employees something to reference and makes the overall goal more transparent. When everyone follows procedure, identifying and preventing mistakes in your inventory accuracy becomes much more manageable.

5. Invest in employee training

If inventory is the lifeblood of your business, then your employees are the heart. After all, they’re the ones who push the inventory through your business by receiving, picking, packing, and shipping. It’s worth investing in their training in order to bring them up to speed on the proper procedures and processes. There’s an initial investment that goes into adequate employee training, but it will go a long way in improving your inventory accuracy in the long run.

Final thoughts

The inventory accuracy formula gives you more than just a random data point—it highlights the efficiency and reliability of your entire business operation. If you maintain accurate records, it’s going to help you optimize your workflow and ultimately improve your profitability.

Improving your workflows involves leveraging tools like warehouse management software, barcoding systems, and cycle counting. Consistently monitoring and refining these inventory processes will lead to long-term business success. We guarantee it!

0 Comments