Key Takeaways

- Companies use an LPN barcode in logistics to track and trace.

- LPN stands for “license plate number.”

- Businesses place LPN barcodes on warehouse moveables like crates and pallets to track them more efficiently.

- Warehouse managers often use moveables as a means of categorizing products.

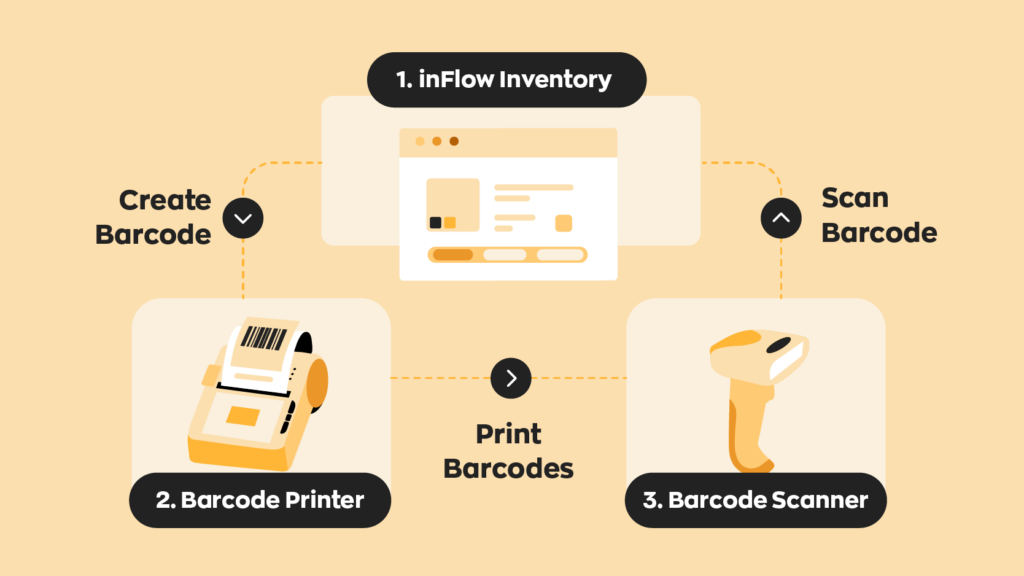

- The workflow requires standard barcoding equipment: Barcode generator, scanner, printer, and software.

Warehouses are a common pain point for businesses. In other words, they’re large, expensive, and require a lot of resources to maintain. At the same time, though, warehouses are a piece of critical infrastructure. They provide storage space for products and are ultimately responsible for getting orders out the door.

Consequently, an optimized warehouse means an improved customer experience, which can give one company an edge over the others.

To improve operations, warehouse managers use many tools for inventory management, a popular one being LPN (license plate numbers) barcodes. Barcodes are an outright necessity in modern-day business and have countless use cases across various industries. An LPN barcode is one of those use cases. So: what are LPN barcodes? How can they help businesses improve warehousing processes?

What is an LPN barcode?

Despite the name, an LPN barcode doesn’t actually have much to do with license plates. Businesses attach an LPN barcode to a larger, movable object, like a crate or pallet. They then use these barcodes to track the moveables as they travel through the warehouse.

The barcodes themselves make use of the same technology as other barcodes. They store information by encoding it into a series of black-and-white stripes. Barcode scanners can read these patterns and translate them into human-readable data.

In that sense, an LPN label is more of an organizational tool than anything else. It’s just a different application of already existing technology.

Why do businesses use LPN barcodes?

Warehouses are very often an organizational nightmare. The average consumer might picture neat lines or shelves of products, but that’s far from the case. Space is expensive, so businesses have a vested interest in using it as efficiently as possible. That means stacking products all the way to the ceiling, which often necessitates heavy equipment like forklifts.

All of this space and equipment, in turn, necessitates more employees, which can create a very chaotic and stressful environment. Notably, the warehouse industry sees a 49% turnover rate in the US– and 150% for Amazon. We won’t make any claims about the warehouse industry, but the chaotic work environment likely plays a role.

From the perspective of a business, a chaotic work environment is a liability. It might sound ridiculous, but misplacing a pallet or crate in a building as large as a warehouse is easy. That’s why they use LPN barcodes. Unlike typical barcodes, which are tied to individual products, an LPN barcode identifies a “container.” These containers may contain multiple items with various SKUs and are an excellent way for businesses to help organize their warehouses.

Amazon LPN barcodes

The most notable company to use LPN barcodes is Amazon. In fact, it’s to the point that their almost synonymous with the company. Many people call them an Amazon LPN label, or an Amazon LPN barcode. And that’s true– Amazon does make regular use of an LPN barcode system. However, it’s a little bit different.

Up above, we illustrated just how chaotic the warehouse environment can be. Amazon is the single largest online retailer in the world (and the second largest retailer, period), and their warehouses are much larger and more chaotic.

This means the amount of product traffic is higher than average– both in and out. In 2021, the National Retail Federation estimated that 21% of all online merchandise during the holiday season was returned. That’s a lot of returns.

One of the ways Amazon uses LPN barcodes is by separating returns as they arrive. This sections off returns from shipments and provides a physical way of tracking returns. Amazon operates on such a large scale that mistakes are commonplace. Their use of an LPN barcode system helps reduce mistakes and increase visibility.

What does a business need to implement LPN barcodes?

There are four necessary components to any barcode system. An LPN barcode system is no exception. Your business will need the following: a barcode generator/designer, a printer, a scanner, and barcode software.

In terms of barcode scanners and printers, the inFlow Smart Scanner and inFlow Portable Printer make an excellent pairing. The Smart Scanner is a rugged Android device with inFlow pre-installed. It’s perfect for scanning LPN barcodes and updating inventory in real-time. Combine it with the Portable Printer, and your team can print labels wirelessly from anywhere. It’s a powerful duo designed with mobility in mind to make LPN workflows fast and frustration-free.

The barcode generator creates barcodes, the printer… prints them, the scanner reads them, and the software ties them all together. If one of these components is missing, things fall apart. It’s important to remember that barcodes are a simple but powerful business tool. Whoever uses them dictates their usefulness, but the key requirements don’t change.

LPN barcodes best practices

If you, as a business owner, are looking to implement LPN barcoding, here are some best practices to consider beforehand.

Make LPN labels accessible

As with any barcode, it’s important to place it somewhere employees can easily access it. While that’s the most important requirement, it’s also far from the only one. It needs to be easy to find, hidden from the elements, and ideally does not require external tools (like a flashlight) to read.

Make LPN barcodes obvious

At the end of the day, businesses use LPN barcodes to separate equipment or products. Meanwhile, some even use LPN barcodes as a way of marking products that are close to expiring. Many businesses do this by directly marking the physical barcode with “LPN.”

Tune the system to your work, not the other way around

The usefulness of barcodes depends on the implementation. LPN barcodes are meant to streamline warehousing processes. It’s important to tune the system to your work instead of changing a business to suit the system. The system itself is malleable– with a little creativity, a solution will arise.

Create a sorting method

Like any inventory management technique, LPN barcodes are only as useful as you make them. With that in mind, settle on a sorting method that makes sense for your business. For instance, you could use an LPN label to store products that sell well together, or you could use them to store products deemed deadstock. The choice is yours.

Final thoughts

An LPN barcode is really just a barcode at the end of the day, and it does what they all do. It stores information. In this instance, though, businesses often use them to separate a certain class of product or equipment. Using them can streamline warehouse processes or open the door to new organizational methods.

0 Comments