Units of measurement (UoM) can help your business get really specific about your inventory levels. They’ll tell your warehouse team how a product will be coming in (e.g., in boxes or on pallets) and they’ll ensure that your customers won’t see any weird quantities on their invoices (e.g., 0.5 boxes instead of 10 sunglasses).

It can be a little tricky to track the various units of measurement on different products, so we’ll go over a few tips in this article.

Why you should track multiple units of measurement

Some items are easy to track because you buy them as bottles, store them as bottles, and then sell them as bottles. But not all product are quite that simple. There are a lot of reasons you might need to break a product out into multiple units of measurement:

- You might be dealing with pipes or wires, which are bought at a certain length and then cut into shorter pieces for jobs or for sale. You can’t just track these items by the meter or foot because that won’t account for what sizes the pieces are cut into.

- You might receive items like sunglasses in boxes or pallets, but store them on the shelves as pairs. So you’ll need to make sure you know how many sunglasses come in a box, and you need to have a system that can recognize that not all boxes are the same size.

In general, you’ll want to to keep three categories in mind when tracking units of measurement:

- How you receive it (Purchasing UoM)

- How you track it (Standard UoM)

- How you sell it (Sales UoM)

You won’t need to have these UoM in place for every single product, but you should always have a unit of measurement that reflects how you track that product (a standard UoM). This way your teams can relate to your products in the way they’re used to doing, without any numbers getting lost in translation when a product moves from purchasing to sales.

It’s also OK to get creative with your units of measurement. If you’re having trouble tracking a product as distinct pieces, you can also use the dimensions or weight as units of measurement.

How to store UoM in a spreadsheet

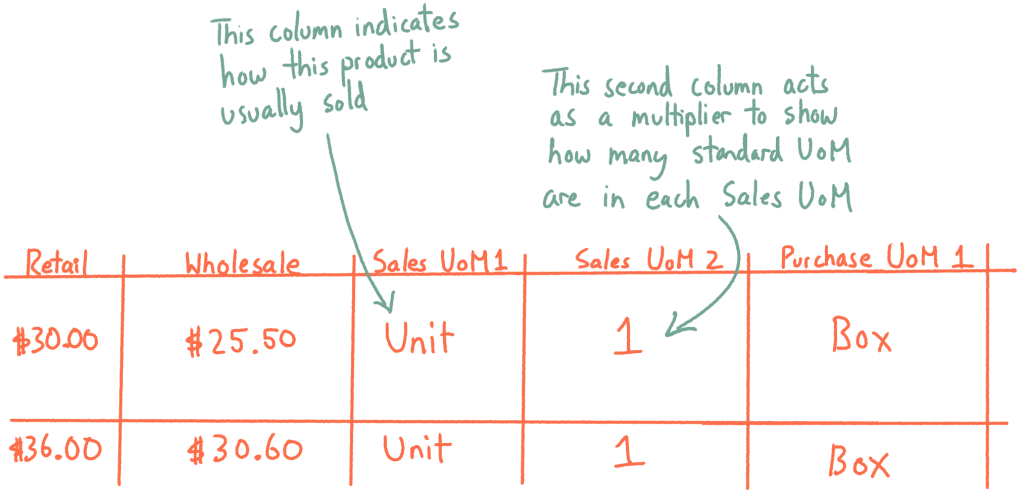

If you’re using a spreadsheet for tracking products, you can add extra columns to track your units of measurement.

But having just one column per UoM type isn’t enough. Taking the example of sunglasses again: if you just say that your purchasing unit of measurement is box, that doesn’t tell anyone how many sunglasses are in a box.

So each UoM type (sales, purchasing) should have two columns. The first column should be the specific purchasing UoM, like box. The second column should then show how many of the standard UoM fit within that container — it’s basically a column that you can use as a multiplier to find out how many standard UoM fit inside of that purchasing or sales UoM.

Here’s what that would look like on a spreadsheet:

Tie your units of measurement to prices and cost

If you tie your units of measurement to your prices and costs, you’ll make it easier to do your accounting and also provide your business with flexibility to sell using different UoM.

We recommend doing this by tying your cost and price to the smallest unit of measurement for that product — which is your standard UoM. So if sunglasses come in boxes but are sold as individual pairs, you’d price and cost per pair and not per box.

Let’s say you buy each pair for $5.00 and sell them for $15.00. This means a full box of six sunglasses would sell for $90 ($15.00 per pair x 6 pairs), and a full box of sunglasses costs your business $30 ($5.00 per pair x 6 pairs).

Track units of measurement automatically with software

A product spreadsheet is a tried and true medium for tracking inventory, but the problem is that it isn’t really scalable. There comes a point where you’ll have too many products to keep up to date, and it can be easier to make mistakes when everything is a grid of rows and columns. You’ll want to switch to inventory software before your business reaches that point.

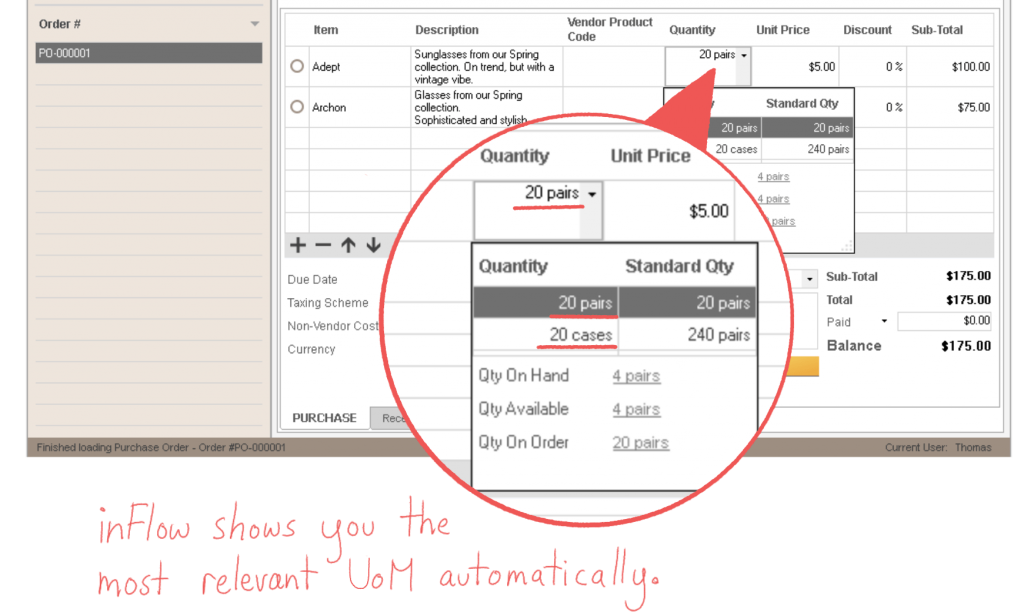

Our software, inFlow Inventory, can help by tying UoM to each product and using each UoM where appropriate. This means you won’t have to remember to use purchasing UoM when buying from a vendor because inFlow will already know that they deal in boxes — and how many sunglasses are in each box.

With proper inventory management software, you’ll see boxes on purchase orders and pairs when you’re counting or selling stock. The right unit of measurement in the right context, with the correct price and cost already attached.

If you have a spreadsheet inFlow also makes sure your hard work won’t go to waste. You can import spreadsheets right into the the program so that you can start where you left off, without having to enter everything all over again.

If you’d like to give inFlow Inventory a try, just click on the link below!

I manufacture knitted fabric and have a slightly more complicated issue for UOM. My received goods (YARN) come in as LBS that are then knitted into ROLLS of fabric with varying weights; which are then grouped into LOTS of varying roll counts for shipping to the customer. Each packing slip lists the lots shipped which in turn are billed by LBS. So although my counting groups are all using LBS for the UOM, my grouping levels make this complicated for how to create a pick list of rolls (serialized barcoded labels) for assembling the lots (barcode for the Lot is the Sales or Work Order #) and then a pick list of lots for shipping and billing. So then my packing slip lists all the rolls that comprise the lot, and my invoice lists each lot shipped for a particular order.

Any ideas on how I might handle this in InFlow? I’m working on the trial version at the moment.

Hi Robin, sorry we missed this comment. I did check your email against our support tickets and it looks like you’ve already had a discussion with us about this, so I hope that helped!