Managing space has always been– and always will be– an important part of running any business. For most small businesses, that means carefully managing their available warehouse space. Unfortunately, as the price of…well, everything, increases across the board, so too does the cost of warehouse space. This makes warehouse utilization more crucial than ever.

Knowing when a business needs more space (and willingness to purchase that space) is important, but so is maximizing the use of what’s already available. In some extreme cases, optimizing warehouse utilization could reduce or even eliminate the need for additional space, at least in the short term.

How to calculate warehouse utilization

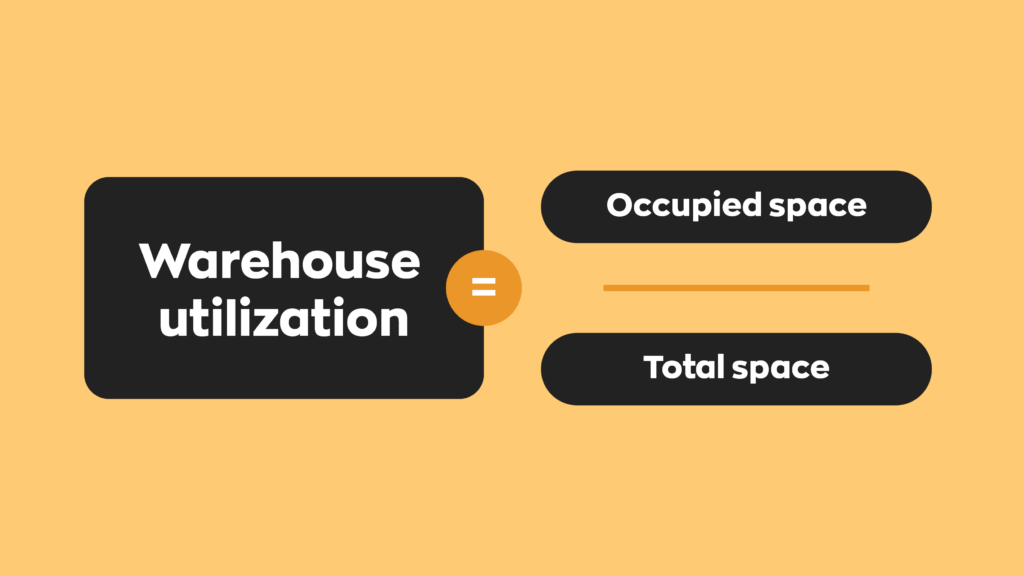

Warehouse utilization (also known as warehouse space utilization) is a figure that measures how much warehouse space a business is using. It can take the form of either a percentage or a decimal.

Calculating warehouse utilization is fairly simple. Divide occupied space by total space. Here’s what that looks like as an equation:

For example, let’s pretend that a business has 100 feet of storage available and currently uses 70 feet. Plugging those numbers into our formula yields the following:

70/100 = 0.7

In this example, the warehouse utilization is 0.7, or 70%.

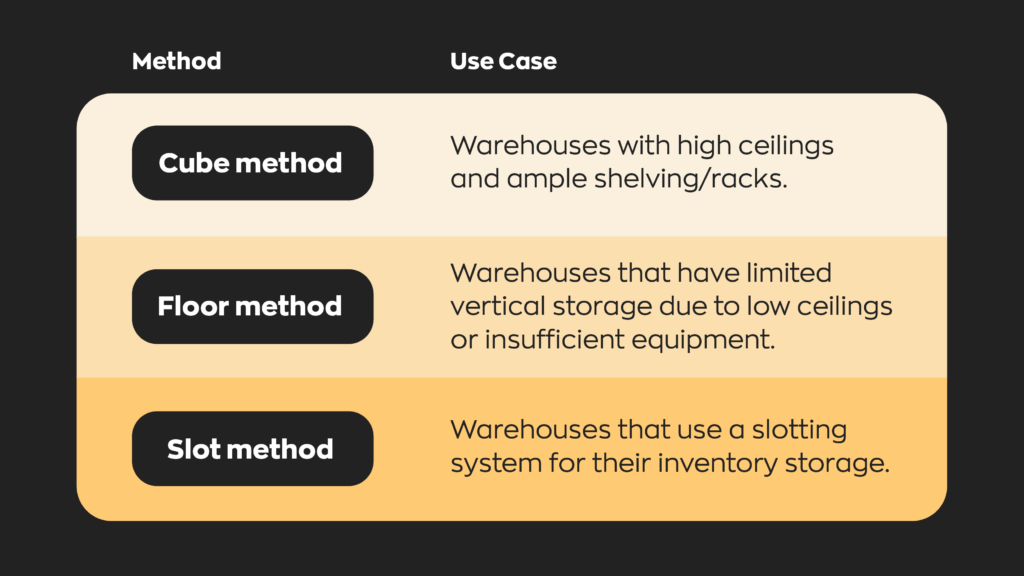

However, there are a few different methods to calculate warehouse utilization. In no particular order, they are as follows:

- The cube method represents volume.

- The floor method represents square feet.

- The slot method represents storage slots.

The method a business uses will change these numbers. Here’s a more detailed explanation of each method and how they affect warehouse space utilization.

Cube method

This method uses cubic feet, or volume, to calculate warehouse utilization. To calculate the total volume of your warehouse, multiply the width by length and then the result by height. For example, let’s say that a warehouse is 10 feet wide, 15 feet long, and 20 feet high.

10 x 15 = 150

150 x 20 = 3000

In total, 3000 cubic feet of space is available. For this example, let’s say that out of that 3000, the business in question uses 1000 cubic feet. Plugging those into our equation above, we get the following.

1000/3000 = 0.33, or 33.33%

If space is taken, it’s taken. So, for the sake of this example, we’ll bump these figures up to 0.34 and 34%, respectively. That means warehouse utilization is at 0.34, or 34%.

Floor method

The floor method is similar to the cube method but cuts out one dimension. It calculates warehouse space utilization by using square feet instead of cubic feet. To calculate available square footage, multiply the warehouse length by width. We’ll reuse the figures from above.

10 x 15 = 150

In total, 150 square feet of space is available. For this example, let’s say that the business in question uses 72 of that 150. Plug those into the warehouse utilization formula.

72/150 = 0.48, or 48%

Slot method

The slot method is a bit more complex than the other two. It relies on warehouse slotting, an organizational method, to calculate warehouse utilization. In simple terms, warehouse slotting involves creating “slots” that your products occupy. The size of these slots will vary from business to business.

For this method, we’ll discard the previous figures entirely and say there are 20 total slots. We’ll also say that products occupy 5 of those slots. Plug those into the warehouse utilization formula.

5/20 = 0.25, or 25%

What is a healthy utilization rate?

You might have noticed that these numbers seem a bit low. The highest is 48%, which means 52% of the warehouse isn’t in use. However, bigger isn’t always better. In most instances, going higher than 85% causes congestion issues; even utilization as low as 25% can be “healthy.”

Product isn’t the only thing inside the warehouse at any given time. Workers need space to move products and equipment; too little free space can prove hazardous.

How can I optimize my warehouse space?

Optimizing warehouse space brings a lot of benefits. Most importantly, it ensures businesses make the most of the space they pay for. This is crucial, especially when considering rising costs. It can also decrease the time it takes your business to expedite orders, increasing customer satisfaction. Here’s a few best practices to improve your warehouse utilization.

Use vertical space efficiently

Making use of all available space is obvious, but using it appropriately is less so. For example, you wouldn’t want a product that’s 2 feet tall to occupy a slot that’s 6 feet tall. It’s a waste of space, plain and simple.

Improve warehouse layout

Optimizing warehouse space isn’t just about fitting more products in the same area. Rearranging pallets and products alike to improve the flow of products can significantly increase productivity. Over time, increasing productivity in this manner pays off.

Implement software

Efficient warehouse space utilization boils down to planning and organization. However, planning the most optimal routes for your inventory flow can be challenging. Software might not be able to do the (literal) heavy lifting, but it can help you better manage your inventory. inFlow’s warehousing software can automatically generate high-efficiency routes throughout any given warehouse, increasing pick-route efficiency.

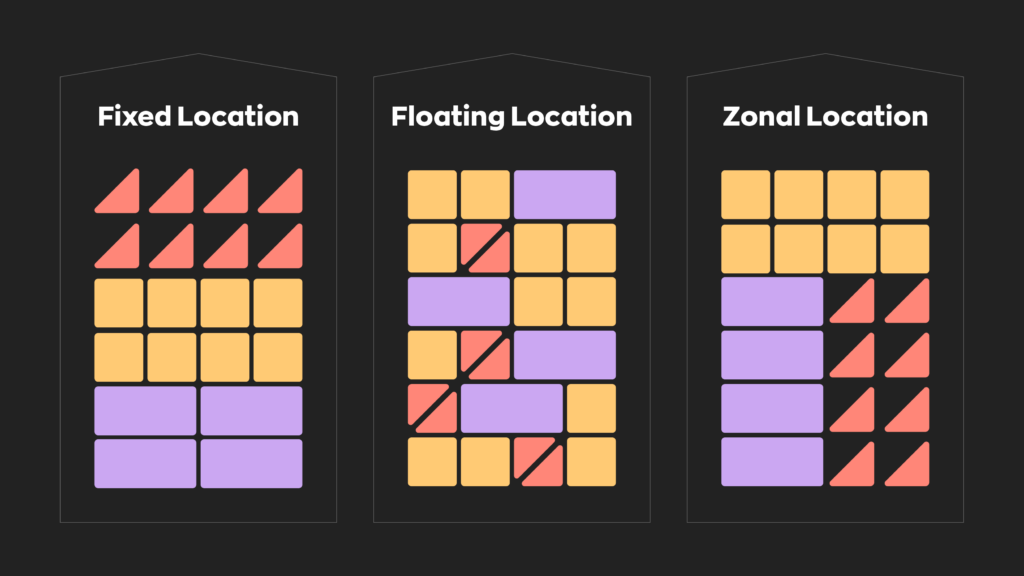

Consider other storage strategies

Of course, it’s also important to consider what warehouse strategy will work best for an individual business. Large products can be difficult to store, but the same goes for small ones. Generally speaking, there are three methods when it comes to organizing a warehouse: fixed location, floating location, and zonal location.

Fixed location

A fixed location refers to a permanent, dedicated storage location for a specific product or stock keeping unit (SKU). Having a permanent location for high-demand products can substantially increase warehouse productivity.

Floating location

The opposite of fixed location, floating location (also known as random location) means storing products wherever they fit. It might sound antithetical to organization, but sometimes product catalogs change frequently. Sometimes, it’s best just to put things wherever there’s room.

Zonal location

A zonal organization scheme involves breaking warehouse areas into specific zones to hold specific product groupings. For example, perishable products might be on one shelf, and non-perishables may be on another. Breaking down warehouses into these zones can increase warehouse efficiency.

Wrapping up

Making use of every available resource is crucial for a business’s health. Optimizing warehouse utilization, especially, continues to remain a key factor amidst rising operational costs. Additionally, optimizing warehouse routes and implementing proper organizational practices continue to play a role in overall efficiency.

0 Comments