How to track damaged goods in inFlow

Depending on your industry, you may want to account for wastage during the assembly of an item or perhaps track the percentage/portion of damaged goods returned by your customer that you end up having to throw away. See the tips below.

Please note: Manufacture orders are only available on inFlow plans with the BOM + Manufacturing add-on.

Handling waste during assembly/manufacture order

When you create a product out of raw materials, sometimes you end up using extra materials or have to throw away damaged ones. This would cause the cost of the assembled item to go up, and you’ll probably want to track that in inFlow!

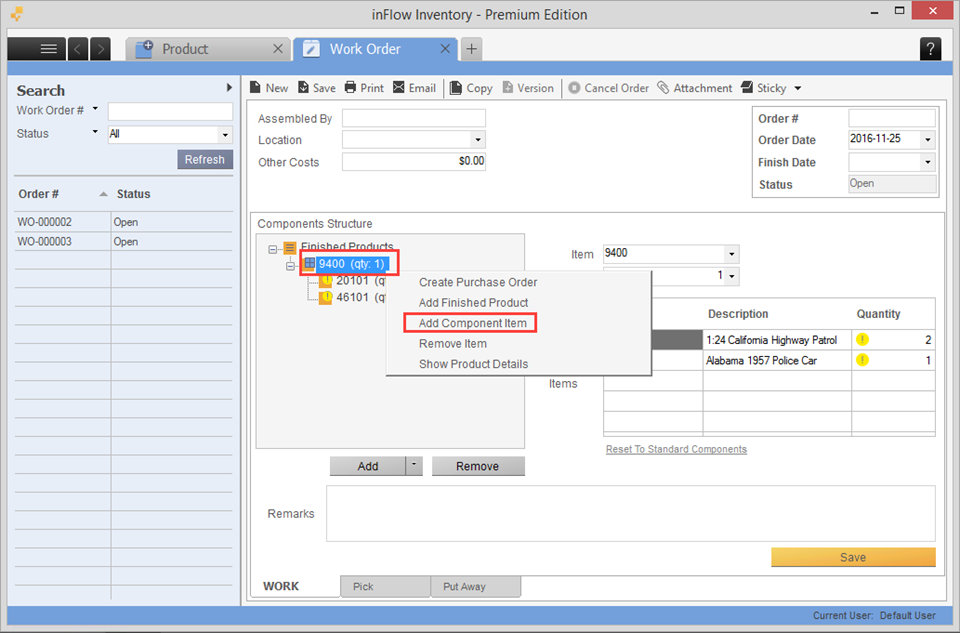

- Create your manufacture order (formally called work order) as usual and start picking the materials you require to finish the order.

- If you find that you have picked more than what was listed in the order, you will need to add it by clicking on the assembled item in the list and then right-click > Add Component Item.

- Add the extra wasted components and then complete the manufacture order.

The materials will be deducted accordingly, and their costs will contribute to the unit cost of this assembly.

Tracking wasted/damaged goods returned by customers

When you process a sales return/refund for your customer, you can choose whether or not to “Discard?” the returned goods. If you check the discard box, you don’t restock them to ensure the inventory levels are correct. However, as inFlow doesn’t natively track the cost of returns in any reports if you’d like to report the number and type of goods wasted, try the following!

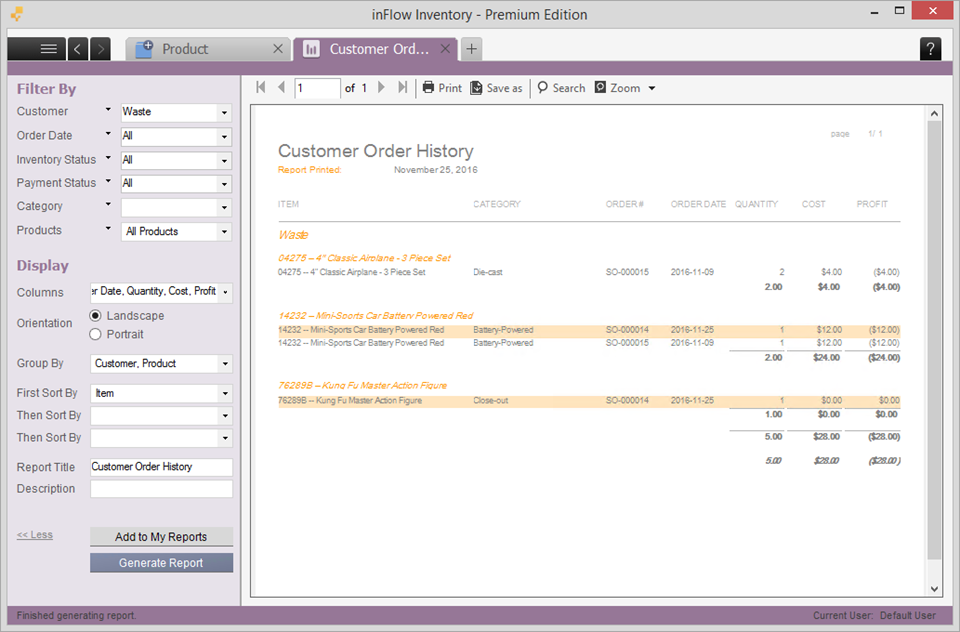

- Create a customer named “Waste” or “Damaged Goods”.

- Whenever you process a sales return/refund, instead of marking it as discarded, restock it.

- Open a new sales order immediately for the customer “Waste” / “Damaged Goods.” Sell the damaged item to this customer at $0 (to correctly calculate the profit loss)

- Complete the sales order.

You can then run a customer order history or sales order profit report for this customer to see the total amount of items wasted or total cost/profit.

need to track discarded items